Treatment of waters coming from car washes

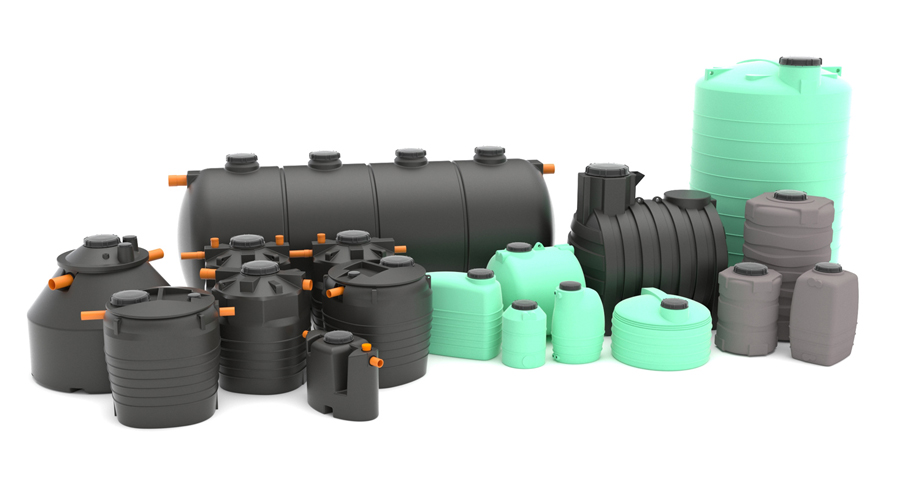

Waters coming from car washes plants are usually full of sludge, sand, detergents, oils, lubricants and residues of polishing products. These, thus, as all sewage, must undergo an appropriate purification treatment before being drained in sewer and in surface waters, in compliance with legislative Decree 152 of 2006. Thanks to the experience and to continuous investments in research, Telcom proposes a process able to solve the sector needs all-around.

TELCOM purification plant for waters coming from car washes provides for the following phases of treatment:

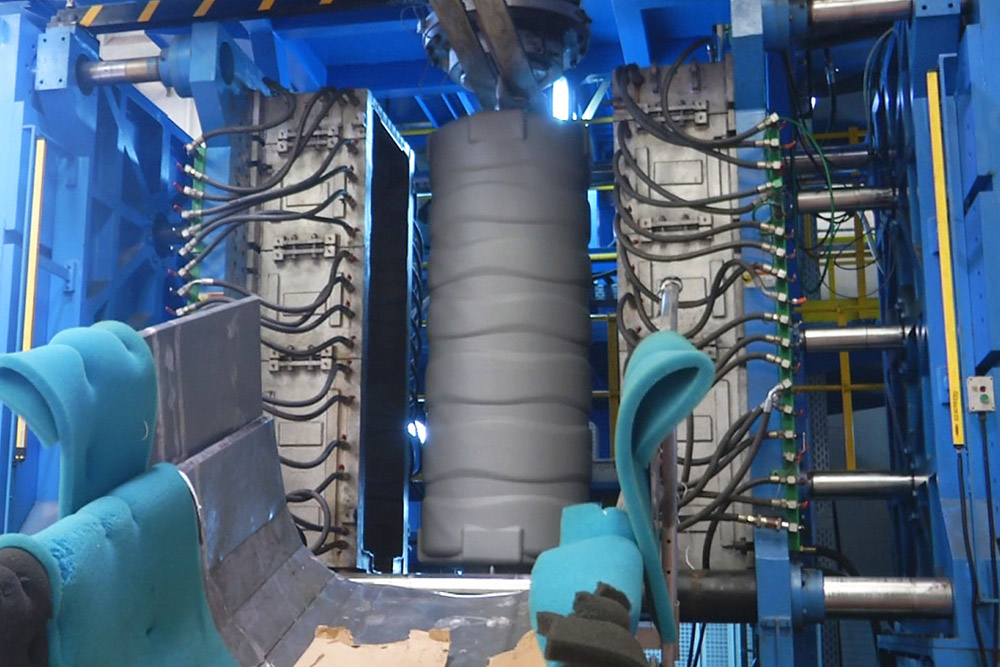

- PHASE OF SAND SEPARATION: sand separator with vertical flow in which is guaranteed the gravimetric separation of sedimentable solids.

- PHASE OF OIL SEPARATION: oil separator which functioning is based on the use of stilling tanks equipped with an internal compartment, which the separated substances are trapped in. The oil separator is equipped with a filter with lamella packs to induce the process of coalescence.

- PHASE OF BIOLOGICAL TREATMENT WITH ADHERENT BIOMASS: Percolator filter with forced aeration which principle of functioning is essentially based on the biological oxidation process with adherent biomass. Inside these percolator filters find their place particular filling corps with high specific surface, which the bacteria flora, of anaerobic type, has the possibility be stationed on, and to set off the purification process guaranteed by the oxidation action of the air blown into the sewage through a system constituted by a blower pump and diffusers.

- PHASE OF CLARIFICATION: tank of clarification equipped with an internal compartment to guarantee sewage clarification.

- PHASE OF INSPECTION: well of inspection for removal of sewage. On the basis of purification needs and draining type the installation of a refinement group with pressure (described below) is planned

- REFINEMENT GROUP: Used for draining in surface waters or on the soil