Primary treatments

In PRIMARY TREATMENTS, physical forces are determinant. They have the purpose of pre-treat the sewage and remove the gross elements that could affect the functioning of the machinery present in the following phases of the plant. In these treatments a first roughing of sewage takes place, in fact a portion of organic load and suspended solids is removed. Precisely for these reason are rarely used alone but always upstream of secondary treatment.

Imhoff basins

Septic basins Imhoff type are units of primary treatment of anaerobic type, constituted by an inferior basin called digester and a superior one called separator. The influent enters the subset of sedimentation that has the goal of holding solid bodies and floating material; from here, it enters the inferior subset of digestion, through the opening present on the bottom of the separator. Digester and separator are sized in such a way that in the first one there is a biological stabilisation of sedimented organic substances (fermentation and anaerobic digestion) and that in the second one that necessary stilling zone that allows a suitable sedimentation of solids present in sewage is created. Periodically mineralized substances, sludges and floating substances must be removed.

Septic basins

Septic basins Imhoff type are units of primary treatment of anaerobic type, constituted by an inferior basin called digester and a superior one called separator. The influent enters the subset of sedimentation that has the goal of holding solid bodies and floating material; from here, it enters the inferior subset of digestion, through the opening present on the bottom of the separator. Digester and separator are sized in such a way that in the first one there is a biological stabilisation of sedimented organic substances (fermentation and anaerobic digestion) and that in the second one that necessary stilling zone that allows a suitable sedimentation of solids present in sewage is created. Periodically mineralized substances, sludges and floating substances must be removed.

Grease separators

Grease separators are used to provide for separation of greases and oils (not emulsified) or sands. In civil drains, particularly in those of certain services as restaurants, hotels, etc. are always present oils and greases and the removal of such substances is necessary because they can seriously compromise the functioning of the following plants of biological purification. The functioning of grease separators is based on the use of stilling basins adequately equipped in which give way to oils and greases (in general to all the substances with a specific weight lower than water) to float and to sedimentable materials to fall. Grease separators are sized bearing in mind of a section useful for the purpose of floating not inferior to 0,25 m2 for each liter per second of incoming flow rate as reported by regulations DIN 4040.

Secondary treatments

SECONDARY TREATMENTS are those delegated to the removal of biodegradable organic substances.

Generally, they are based on biological processes and are the treatments most responsible for sewage purification.

Active sludges

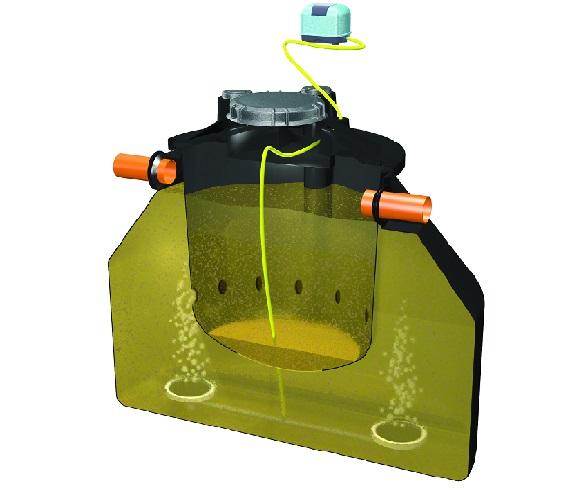

Active sludges plants are purification elements of biological type with suspended biomass and prolonged aeration. They are defined “biological” plants, because the degradation of the organic substance, and part of suspended solids, takes place through the action of bacteria that feeding on polluting substances purify the sewage. Sewage artificial aeration guarantees the proliferation of such bacteria that grouping in colonies create the “sludge flakes” typical of suspended biomass. Active sludges plants are composed by two compartments: one of oxidation and one of sedimentation. In the first, the slurry is subjected to an artificial aeration treatment and in such an oxygen-rich environment physical, chemical and biological processes set off degrading the pollutant load. High microbial concentrations present into the aeration vain are guaranteed by the continuous recirculation of active sludges collected in the following sedimentation vain. In it, separation and precipitation of sludges take place, and then they recirculate in oxidation vain. The clarified and purified sewage is sent to subsequent phase of treatment eventually scheduled. Only the sludges produced in excess compared to the needs of purification process (surplus sludges) must be periodically removed from the plant.

Percolator filters

The percolator filters are secondary treatment systems of biological type and adherent biomass. Inside such plants, particular filling corps with high specific surface are accommodated and upon them bacterial colonies responsible for the purification of sewage are developed. The ECO FAN percolator filters are anaerobic because the developing type of bacteria lives in the absence of oxygen. A correct installation of a plant with percolator filter requires always a unity of primary treatment upstream. Aerobic percolator filters with low output are available on request. In case of such plants the installation of a second clarification tank (smaller than the first one) also downstream, for biofilm examination is necessary.

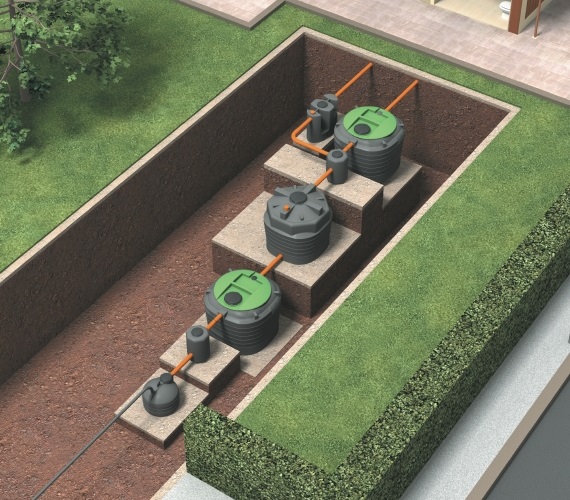

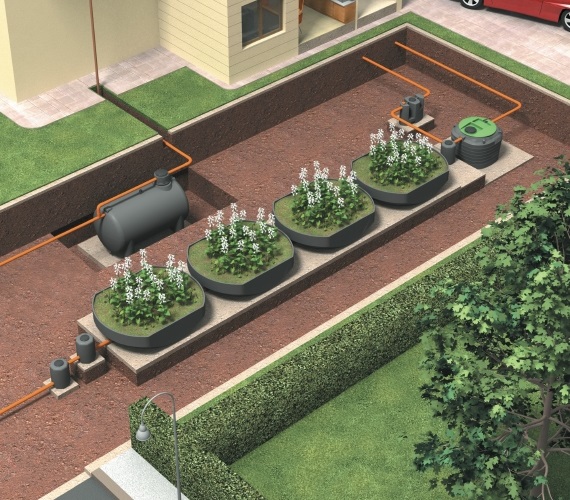

Phytopurification

Phytopurification is a natural purification system allowing refining pre-treated sewage triggering both aerobic and anaerobic processes, typical of aquatic environments and wetlands. The purification effect takes place thanks to the continuous action of digestion and assimilation of the substances contained in the sewage through the root systems of shrubs, grass and flowers, constantly lapped in the appropriate trays by clarified waters. TELCOM Phytopurification plants are system with submerged horizontal flow and they are composed by trays containing inert material (gravel and crushed stone are commonly used) on which emerging plants roots develop. The level of sewage inside the trays is kept constant thanks to the installation of a well downstream the trays and the flow runs horizontally. It is always necessary to foresee upstream of phytopurification trays a primary treatment of sewage. In case of separated drains, it is generally recommended a grease separator for grey water and an Imhoff basin for black water, while in case of combined drains a tricameral tank is better.